Dust collectors are an important consideration for your facility, and worker safety. Choosing the right type of duct collector will have an impact on air quality in your workplace. Cartridge dust collectors are often used in facilities where very sub-micron particles must be filtered, or where continuous filtration is a requirement.

How Do Cartridge Dust Collectors Work?

Cartridge filters are made from pleated material, and the particulate is collected on the outside of the filter media. These filters are usually cylindrical in shape and this form may be reinforced by metal mesh or fabric bands. The pleated material may be made from a polyester-cellulose blend, and the outside of the filter has a specialized coating, matching the application it is being used for. Cartridge filter coatings may include nanofibers (increasing filter efficiency), spunbound material (adding durability under exacting conditions), PTFE fibers (non-stick), hydrophobic coating (water-resistant), or oleophobic coating (oil-resistant). Other filter coatings may be anti-static or fire-retardant.

Small cartridge dust or fume collectors may have as few as two or four cartridges. Though for large manufacturing plants, dust collection units with dozens or over a hundred cartridges are not uncommon.

How Cartridge Collectors Filter Particulate

Diagram courtesy of Donaldson

Diagram courtesy of Donaldson

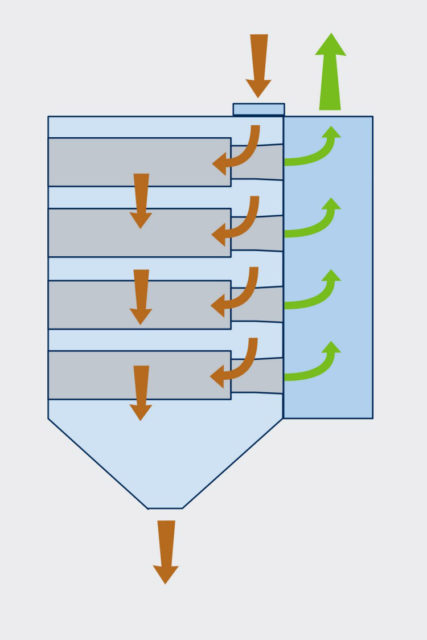

Dirty air enters through an inlet, and passes through the space where the filters are. The cartridge filters may be mounted either horizontally or vertically. The dirty air passes through the filters, and particulate is collected on the outside of the filters. This area is known as the dirty air plenum. The air passes through a drop-out zone and clean air moves through the clean air plenum before exiting through a clean air outlet.

When they initially appeared in the 1970s, cartridge dust collectors were mostly vertically aligned, to mimic the airflow of baghouse dust collectors. In the last decade, more cartridge filtration units are horizontally aligned. This makes it easier for particulate to drop-out towards the collection hopper.

An additional upside to horizontally aligned cartridge filters has to do with explosion prevention. In horizontally aligned cartridge collectors, explosion relief vents can be location on the roof or side of the unit. To contrast, in vertically-hung cartridge collection units, the explosion vents must be located on the side of the unit. This requires expanding the footprint of the collection unit, in order to divert the vents upward. Horizontally placed cartridges are generally preferred because in event of deflagration, the discharged materials are pointed upward, and away from workers on the facility floor.

Cleaning Cycles in Cartridge Dust Collection Systems

Most cartridge dust collectors used a pulse jet cleaning cycle to remove particulate from the filter media. A pulse of compressed air travels down the filter media, going in the opposite direction from the air intake. Some cartridge collectors use energy saving pulse jet systems to keep the filters viable while conserving energy and compressed air.

Industries That Use Cartridge Dust Collectors

Cartridge dust and fume collectors are well-suited for work areas that require filtration of very fine particulate. Here are some applications where cartridge filter units are commonly used.

- Welding fume extraction

- Grain silos

- Laser or plasma cutting

- Woodworking

- Fiberglass manufacturing

- Abrasive blasting

- Smoke filtration

- Chemical or plastics production

- Pharmaceutical

Advantages of Cartridge Dust Collectors

Plant managers choose cartridge dust collectors when a smaller, more compact footprint is preferred. Cartridge dust collectors tend to have more filtering capacity per square foot versus a baghouse dust collector. Another advantage of cartridge dust collectors is ease of maintenance. Changing the filters can be done quickly from the outside of the unit. With some baghouse units, changing the bag filters means accessing the inside of the collection enclosure and changing the bags one by one.

Though many cartridge dust collectors are placed outside the walls of the industrial facility, these can be placed inside the building if necessary. This is usually not possible with baghouse filtration units, due to the larger size needed for airflow.

Baghouse vs Cartridge Filter System: Which Should You Use?

There isn’t a “one-size-fits-all” answer to this question. Both cartridge and baghouse filtration units have their advantages and disadvantages. Ultimately, each type of dust collection system will be best suited for specific types of applications.

For cases where sub-micron filtration is necessary, or a smaller footprint is unavoidable, a cartridge dust collector may be better suited for your shop.

In harsh conditions, such as extremely high temperatures, a baghouse collection system may be the best choice. Baghouses also work well in many cases where the particulate is contaminated with oil, moisture, or certain abrasives.

When in doubt, consult a dust collection specialist. Preferably a air quality consulting company that handles many types of dust and fume collection, that has no hidden motivation to sell you a solution that may not be the ideal fit for your facility.

Need a Dust Collection Consultation?

If your facility needs dust collection or fume extraction, IAF can help you make an informed decision, design a dust collection system, automate filter stocking, or install the right equipment for your workplace.