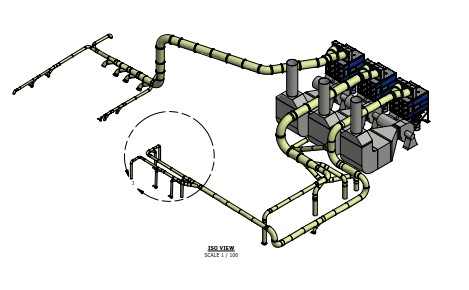

Dust Ventilation

Perhaps you have a dust issue in the plant and you need to add or improve your overall dust collection. We can help you identify the main dust generating offenders and design countermeasures to collect the dust properly. We use advanced 3D ducting design software to analyze system airflow and can help you optimize the potential or your existing collector or help you add more capacity with a new or additional unit.

Dust Collection Explosion Protection

Improper handling of combustible dust not only usually results in costly and public fines for not following OSHA, local, and NFPA guidelines, but it puts the safety of your employees, community, and assets in danger of a devastating explosion. Combustible dust could be any organic or metal particulates that are the result of processing or handling bulk materials, especially scrap product.

These fine particles can create an explosion hazard when suspended in air. If you have some form of dust ventilation, the confined dust in a baghouse can ignite from a spark or static electricity causing a detonation. This pulse wave from the initial explosion can disturb and aerate accumulated dust off of equipment or roof rafters which can then cause a more severe secondary explosion that can devastate the entire building. Understanding the characteristics of the dust being handled in your facility is the first step in identifying the potential fire or explosion risk present. OSHA identifies any dust with the deflagration index (Kst Value) higher than zero, such as sugar, as a potential for a deadly explosion.

We can walk you through the steps of identifying your explosion risk, designing your ventilation system to isolate and or suppress explosions, and manage the installation of the new equipment or retrofit of explosion safety devices.